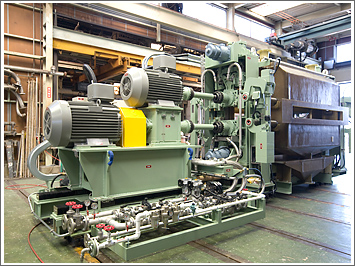

Brushing Equipment (Drive side)

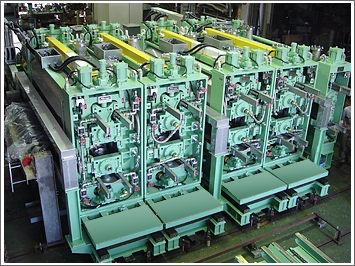

Brushing Equipment (Work side)

The brushing stand is designed to maximize the Cleaning/Abrasive performance of brush roll.

Also, the stand has advantages of space saving, easier maintenance inserting/drawing out of brush roll.

Also, the stand has advantages of space saving, easier maintenance inserting/drawing out of brush roll.

Advantages

TOP/BOTTOM brush roll (Brush-Brush) system is adopted. It makes possible to save the space about half of its conventional Brush-Backup Roll system. In addition, because there are No back Up Rolls, the maintenance cost can be reduced.

TOP/BOTTOM brush roll (Brush-Brush) system is adopted. It makes possible to save the space about half of its conventional Brush-Backup Roll system. In addition, because there are No back Up Rolls, the maintenance cost can be reduced. The vibration which will cause chattering marks on strip surface and contributing to bearing damage can be reduced. As shown in the picture, the beat point between strip surface and TOP/BOTTOM brush roll is the same. Therefore, the vibration can be reduced.

The vibration which will cause chattering marks on strip surface and contributing to bearing damage can be reduced. As shown in the picture, the beat point between strip surface and TOP/BOTTOM brush roll is the same. Therefore, the vibration can be reduced.- Brush roll can be drawn out by side (Work Side) easily, thus, roll Changing time is drastically reduced. In addition, the joint part between motor side and brush side is remodeled. There is no need for disassembling work at joint part on Motor (Drive) side. Hotani provides five different types of original roll changers from full-automatic to manual type. For more details, please confirm Brush Roll Changer List.

Functional options

1.Oscillation System:

The system moves brushing equipment toward strip width direction back and forth as it detects both side of strip edges. Brush roll becomes worn evenly with using this system. Therefore, uneven wear is reduced and smooth brushing toward strip surface is performed. Also, Brush roll life will be longer because full brush roll width is used.

![[WITH] & [WITHOUT] OSCILLATION](img/03/img_03_01_008.jpg)

2.C-camber Correcting Device:

The equipment makes c-shape strip flat at the brushing point with squeezing rolls. The equipment is used to even brushing performance toward strip width direction and to reduce the possibility of brush roll damage.