Hotani original technology is highly admitted all over the world.

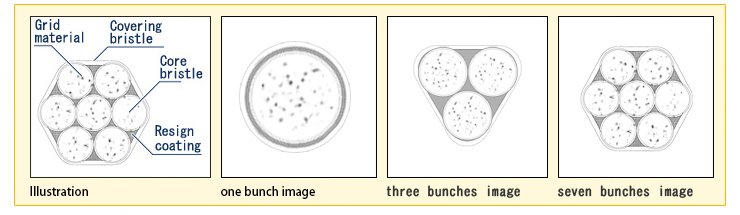

Multiple filament process

●Characteristics

"Multiple filament" is the original bristles, which are combined with several core yarn and manufactured at our factory, and is covered with micron-size nylon. This original process helps to bring out the variety of the brushing performance.※Transmission of Force…The thicker the root of brush roll, the more elastic brush bristle.

※Brushing performance…Fine brushing is possible by making bristle tip thinner.

Disk type

Disk type means making a hole in a round-shape steel plate (disk), and then assembling brush bristles with the brush disk. One brush roll consists of a brush roll shaft and assembled with brush disks. Hotani only manufactures disk type brush rolls, which realize a constant high quality brushing during long term use. The main advantages of disk types are the followings.

●Advantages

1. High density :

The density of a brush roll is controllable by adjusting the number of disks, which enables gaps to be minimized among brush filaments. Especially, when the homogenization of surface quality is required, controlling the density is effective to bring out the performance of brush roll. In addition, it is applicable for very aggressive brushing like descaling due to keeping the high density for a long period.

2. Easy repair :

Brush bristles are filled into each hole so that it can be prevented from continuous falling-out of bristle. In case of the defect, partial repair can be possible by replacing the damaged disks with new ones.

3. Ideal structure :

We can offer three types of the disk specifications. It is selectable according to the purpose of brush roll.

Cassette brush

Cassette brush is the segment typed brush glued several disks together and set into a certain dimension. The segments are easily assembled into the brush shaft with specific tools.

Cassette brush is the segment typed brush glued several disks together and set into a certain dimension. The segments are easily assembled into the brush shaft with specific tools.

●Advantages

1. Reduction of the delivery cost :

There is no need to transfer brush shaft. Therefore, delivery cost for supplying/delivering of brush roll can be reduced.>Click here to open the chart drawings of the trasnferring cost reduction.

2. Reduction of the spare shafts :

The cassette assembling is possible to complete at customer site. The advantage is contributed to stock the minimum quantity of spares.[Comparison of spares]

3 sets are recommended in the "traditional type"

1 set are recommended in the "cassette type".

>Click here to open the chart drawings of the spare shafts reduction.

3. Improvement of the brushing quality :

The gaps between cassette brush and shaft are reduced by locking each segment with special keys. By its lock system, the shaft wear can be drastically reduced. The shaft wear can be a cause of an unbalance, a trembling of the brush roll, and the occurrence of chatter marks on the strip.

Custom-made brush system

Hotani brush product is manufactured from raw materials through the fully-integrated production process. By consistently manufacturing system, we can offer you the custom-made product which can be met your expectations.

>Go to Brush production process

>Go to Brush production process